FGIS REGULATIONS

(FEDERAL GRAIN INSPECTION SERVICE)

Typical procedure for installing and operating a mechanical sampling system is as follows:

- Submit a written request, with drawing of proposed sampling site, to the chief inspector of your local inspection agency.

- Inspector will contact you with information regarding definitions of elevator safety, accessability, lighting, mixing or blending, return to excess sample, adding or diverting material from stream, location of sampling equipment, communications.

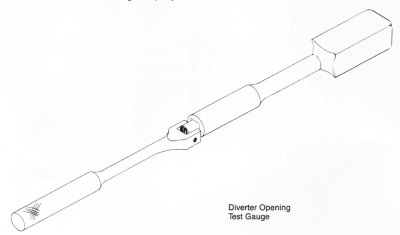

- After installation, the sampling system will be check tested by the local inspection agency according to FGIS regulations. If the commodity used for checktesting is corn, the sampling system will be approved for all grains. If corn is not available, the sampling system can be approved by checktesting the system with soybeans and one other small grain. Corn will not be approved in this case. The inspector will use a pelican or ellis cup to obtain samples while the mechanical sampler is obtaining samples. Deviation of the two samples must not exceed 10% for any factor.

For complete information regarding FGIS regulations, contact your local inspection agency for a copy of th most current issue of "IN INSTRUCTION 916-6, REV.1"

GAMET HOME | SERIES 6800S | SERIES 6800L | SERIES 6400

SERIES 6200 | SUPPORT EQUIPMENT | ELECTRICAL

SPECIALTY EQUIPMENT | FGIS REGULATIONS

Email: [email protected]

Calibration Plus 34 W. Hacienda Lane Woodland, CA 95695 Phone 530 662-7752 Fax 530 662-3998 Mobile, Voice Mail 530 848-2970